Customer pain points:

The homogeneity of laser cutting equipment is serious, the market competition is fierce, and the needs of end customers are becoming more and more stringent.

1. Greater laser power requires higher-performance CNC, servo and transmission systems;

2. Improve the processing technology according to the influence of laser cutting process parameters;

3. Automation, intelligence, and industry 4.0 technology;

4. Multifunctional laser processing center, integrating laser cutting, laser welding, etc.;

5. Three-dimensional high-precision large-scale CNC laser cutting machine and cutting process technology.

The secret of success:

1. More than 10 years of experience in system application of various models in the laser cutting industry, serving customers in the top ten in the industry;

2. The plan is calculated through scientific selection and calculation, and mature design modules are used;

3. One-stop supply of high-performance components with reliable quality, and local warehouses in South and East China.

The advantages of Xiangju:

1. Rich experience in plane cutting, pipe cutting, three-dimensional laser processing and other fields, covering mature low-, medium-, and high-profile Cost-effective system solutions;

2, provide a complete set of services such as product selection, design analysis, electronic control debugging, process writing, interface development, industry 4.0 integration;

3, fast response to delivery, rich products , Provide one-stop centralized procurement services from control to drive, to transmission, etc.

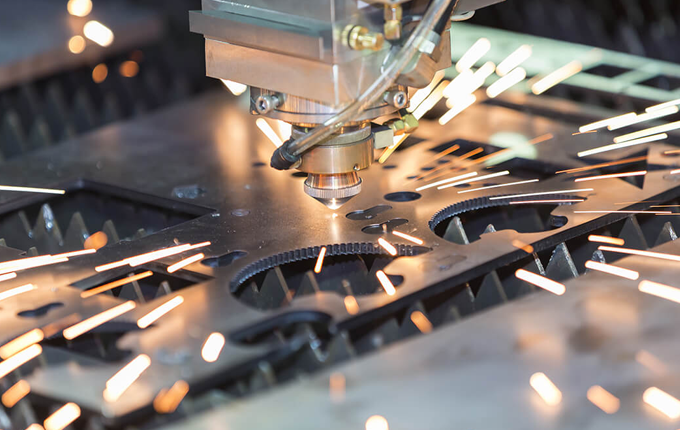

Plane laser cutting machine

Laser pipe cutting machine