Customer pain points:

1. There are mostly semi-closed-loop five-axis control systems on the market, with serious homogeneity, low machining accuracy, and weak competitiveness;

2, high-precision full-closed loop The cost of the five-axis control system is high, and there are application authorization restrictions;

3. The lack of five-axis CNC machining application experience and mature five-axis machining process solutions cannot meet the market's increasing demand for high efficiency and high precision;

4. The ability of the whole process solution from five-axis mechanical design to workpiece processing is relatively weak, and it is difficult to develop a market-oriented five-axis CNC machine tool.

The secret of success:

1. Solve the problem of micro-hole processing speed fluctuations, which can process 0.15mm micro-holes;

2. Solve the problem of linear to arc speed deceleration, R2 fillet processing speed is 300MM /S, high-speed processing with 3G acceleration;

3. Solve the problem of expensive RTCP function and provide cost-effective solutions;

4. Interpolation cycle of up to 0.25ms ensures high-speed and high-precision processing;< br/>5. Direct drive technology is used to solve the problem of screw backlash and turning pause;

6. IMS closed loop is used to solve the problem of transmission thermal extension;

7. To solve the problem of product Yin and Yang line;

8. Solve the crease problem of processed products;

9. Solve the rigidity problem of linear motor machine tools. We provide rigid analysis of mechanical design, linear motor installation standards and testing methods;

The advantages of Xiangju:

Excellent and complete team provides diversified services: selection, design, electronic control debugging, process testing, interface development, 20 years of process experience , Rich industry cases.

1. There is a mature and stable five-axis linkage CNC system that supports RTCP and has been widely used by domestic and foreign machine tool manufacturers;

2. It has the ability to solve the whole process from five-axis mechanical design to workpiece processing, effectively ensuring that customers can achieve their expected goals;

3. It has the functions of automatic correction of the five-axis rotation center and online workpiece measurement, which improves the degree of intelligence and avoids the tolerance caused by man-made;

4. Personnel with extensive five-axis machining application experience, and mature five-axis process solution capabilities;

5. We have not only implemented many successful cases, but also many improvement cases, which can greatly increase the success rate of the project.

Cradle type five-axis machine

Processed Products-Impeller

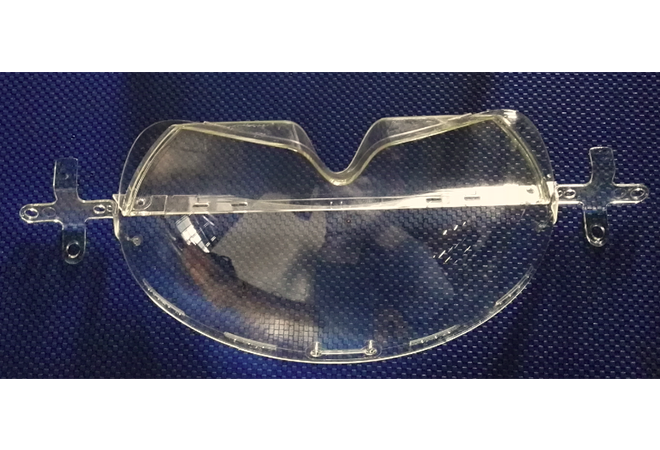

Processed products-VR glasses